| Japanese | English |

It is said that some people can diagnose the performance of a motor only by hearing its operation sound. Such abilities are obtained by a complex learning process. Their brain may grasp key features of sound and perform a difficult discrimination task. I believe that the similar task can be achieved by analyzing sound. As a starting point of the analysis, the rotational speed of a 12V motor for the slot racing (the maker is MABUCHI MOTOR) was estimated from its operation sound.

| Date: | 14 Jul. 2002 |

| Place: | Apartment (Tokyo, Japan) |

| Microphone: | SONY ECM-MS907 |

| Personal computer: | SONY VAIO PCG-R505R/DK (RAM: 256MB) |

| OS: | Windows 2000 Professional |

| Software for reproduction: | Windows Media Player |

| Software for Measurement: | Realtime Analyzer of DSSF3 |

A motor is placed in front of the microphone. A microphone is a one spot stereo microphone SONY ECM-MS907. Other microphones can also be used. See this page for information about the measurement equipment.

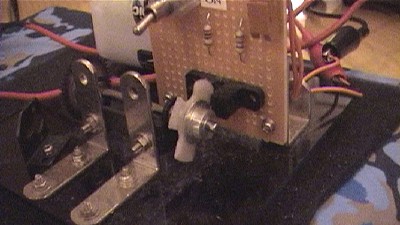

This is the stabilized power supply equipment for 0-20V. It was used as a power supply of the 12V motor. Probably, 12V battery may be used. If you use a 1.5V or 3V motor, dry battery is also available.

Sound level meter is used to measure a sound pressure level. ACO Sound Level Meter TYPE 6146 was used. Sound level meter is not needed if we measure only the rotation speed.

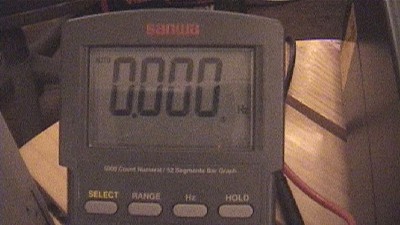

By the SANWA PC500 digital tester (DMM)'s frequency counter function, the rotational speed of the motor is measured. It was used to prove the sound measurement result.

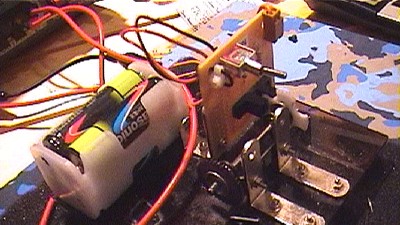

Test bench was built using photo interrupter.

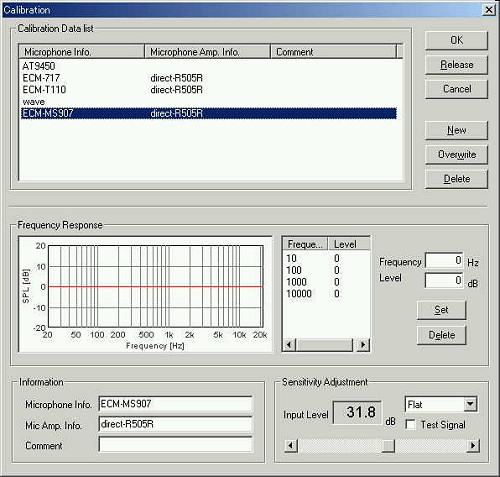

Start Realtime Analyzer and open the FFT analyzer. Since this microphone is used first time, I calibrated its input sensitivity. Below is the calibration window called from the FFT analyzer. In the Edit screen, enter "ECM MS907" into "Microphone info." This microphone is directly connected to the microphone input terminal of the laptop PC. So I entered it as "direct". Direct means that a microphone amplifier such as DAT recorder is not used. The purpose of this experiment is to measure the rotational speed of a motor using the minimum apparatus.

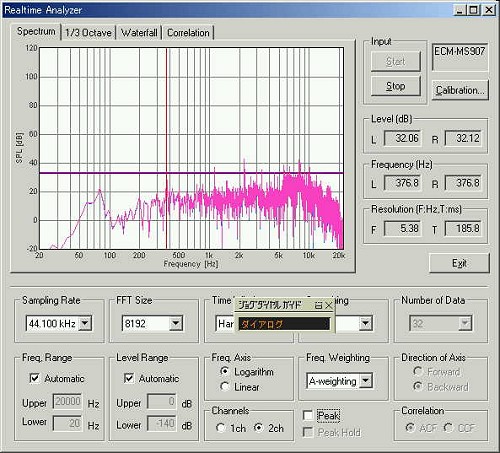

Without the motor sound, the sound level meter reading was 32 dB. I placed the microphone close to the sound level meter and adjusted the input level as above. Then the microphone data for MS907 was registered.

Now, I'm ready for the measurement.

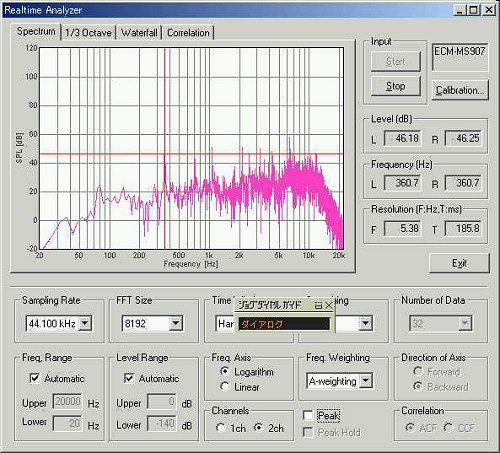

The motor measured in this experiment has a rotation speed of 20000 rpm. The measured sound should have a fundamental frequency of about 330 Hz (i.e. 20000/60=333.33). To measure the sound of a motor, choose " microphone" as the input device and choose the calibration data of MS907. Then open the FFT analyzer's power spectrum. To reduce the influence of low and the high frequencies, set the Freq. Weighing as A-weighting.

Start the motor and record sound with a microphone.

Results

Click the peak around 300HZ on the power spectrum display. Peak frequency and its level is displayed in the right of the graph. This is the fundamental frequency of the motor sound.

No. 4 Motor: 376.8 Hz, 22560 RPM

The rotational speed of a motor is measured physically too. A motor is attached to the apparatus. Ten gears are attached to a motor, and a super gear with 40 teeth is turned. The feather in the end has four slits in one rotation.

The sensor with an optical transistor detects those slits. The rotational speed is measured by the number of slit detected. Measured speed is 374 Hz. This is the similar value as that measured by the sound analysis. The speed is measured somewhat low because of time delay to turn a gear.

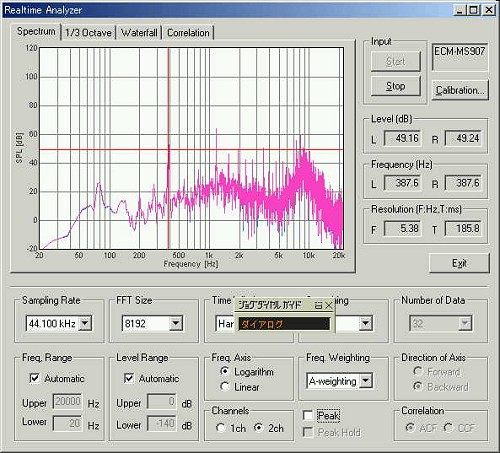

No. D1 Motor: 387.6 Hz, 23220RPM

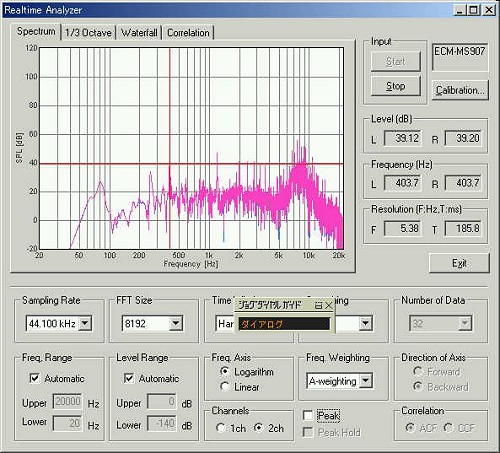

403 Hz, 24180 RPM

No. R13 Motor: 366Hz, 21960 RPM

As were shown, the power spectrum is a convenient method to measure the frequency components of sound.

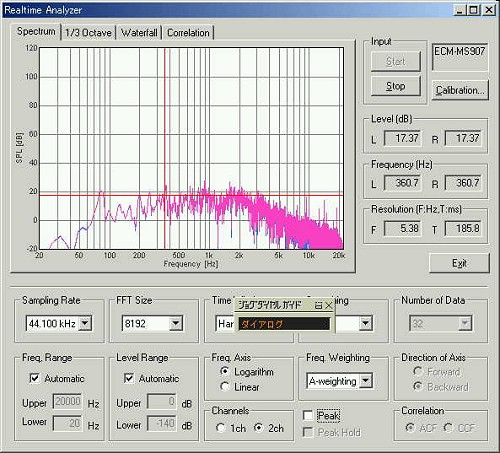

When the motor stops, the spectrum of the background noise is measured.

As this experiment shows, the rotation speed of a motor can be measured correctly by its operation sound.

July 2002 by M. Sakurai